Quality Management / Certification

MKV does not leave anything to chance, because our quality is your success!

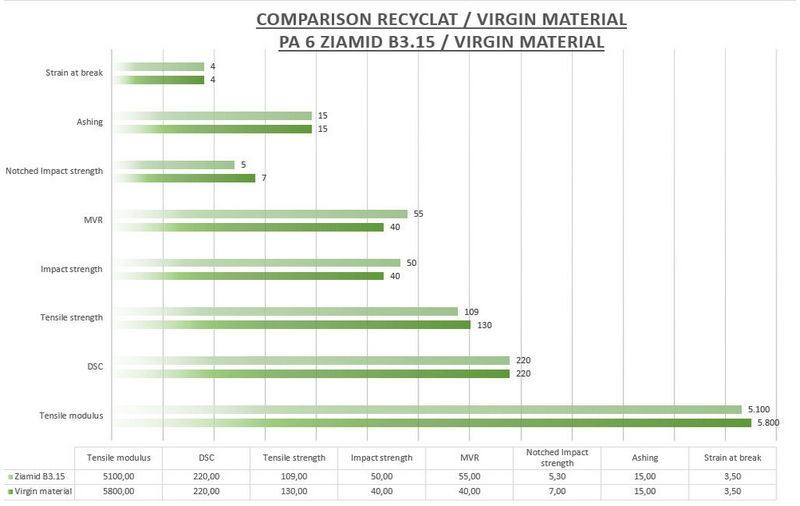

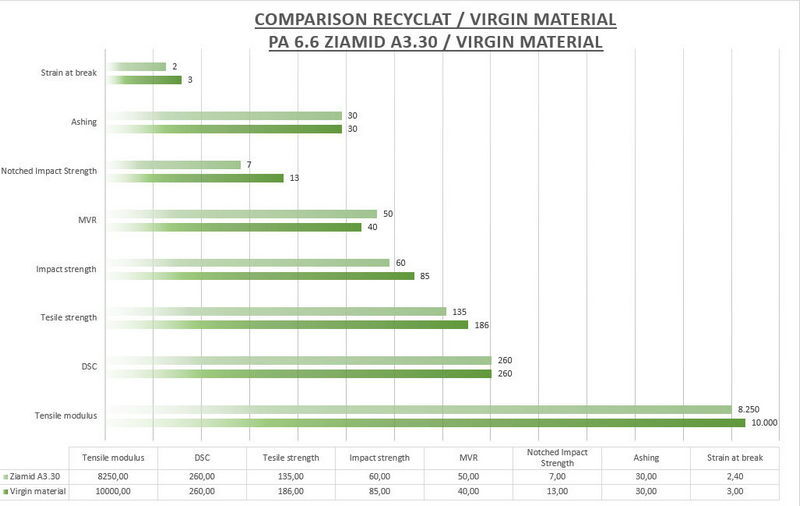

Not everyone can produce a high quality recyclate. Our ZIA-compounds can be benchmarked against virgin material and provide a real alternative. Consistent and continuous quality controls throughout the entire production process make this possible. Starting with the material sourcing from post-industrial sources to the ground material, all the way to the finished granulate, our quality is determined by a clear material stream management.

All materials are subject to a strict incoming goods inspection.

To produce a granulate that meets the high expectations of manufacturers, the materials have to be unmixed and free of contamination.

Every batch is premixed to ensure a homogeneous regrind from which a sample is extracted and test-extruded. First conclusions can be drawn from this about the quality of the incoming material, and it allows for a first optical inspection.

Material testing – thermal, rheological, mechanical

For our customers to be confident that our product meets the expected material characteristics, we determine and document a number of parameters. For maximum precision, we analyse all materials in our very own and state of the art laboratory for their

- thermal,

- rheological and

- mechanical

parameters according to standardised test procedures. By means of differential scanning calorimetry, short DSC-analysis (see here for a video), all materials are tested for their purity. Besides determining the type of polymer, due to its material specific characteristics, information about glass transition temperature, melting temperature and the degree of crystallinity are recorded. Only unmixed materials are processed further to become high quality regranulates and compounds.

Our experienced lab-technicians also test the flowability of each product. The melt volume-flow rate (MVR) analysis covers the rheological part of material testing.

The flowability of the melt of a thermoplastic polymer is decisive for the further processing at the customer. The MVR-value ensures that no big fluctuations occur between batches, which would negatively affect the productivity as well as the quality of the finished product.

Further, mechanical properties are determined with the aid of test specimen, produced with our own injection moulding machine, via tensile test, impact strength, and notched impact strength test.

With the tensile test the stress-strain behaviour of the plastic is analysed and typical material characteristics are recorded, such as:

- strain at break (at which relative changes in length the material yields)

- tensile strength (maximum strain a material can withstand without fracturing)

- and elastic modulus or E-modulus (describes the resistance of a material against deformation up to the point where the deformation would be permanent)

The impact strength, and notched impact strength test (the test specimen is notched prior to the test) according to Charpy define how impact-resistant the material is, i.e. how well it can absorb the energy of an impact.

Incineration is used to determine the filler content of the material.

For tests or parameters which we cannot determine ourselves despite our broad spectrum of analysis we work with an external laboratory if required.

Quality made in Germany

Our comprehensive quality management guarantees that our regranulates and compounds are of consistently high quality. The composition of homogeneous mixtures provides the basis for that and ensures process reliability for the customer.

To produce a compound with the desired product characteristics we use only high-quality products for our additives, i.e. fillers, reinforcers or colours.

All of our products are compliant with RoHS and REACH and you may receive a material data sheet and test certificate for each.

As a leading recycling business in the plastics industry for thermoplastics, MKV GmbH Kunststoffgranulate offers a sustainable product portfolio, which meets the ecological and economical demands of our customers. Made in Germany – with everything it stands for!

ISO 9001 und ISO 14001 certified

The quality and environmental management systems of MKV GmbH Kunststoffgranulate are certified according to ISO 9001 and 14001. Our quality assurance spans across all business areas as it involves every employee.

Besides the high quality of our services and products, social responsibility is another important factor of our daily work, which is why we have joined the TecPart (Verband Technische Kunststoff-Produkte e.V.) code of conduct.

DIN EN ISO 9001/14001 certificates

TecPart Code of Conduct